Transformer core

Transformer core is made of CRGO silicon steel material; it is an internal part of an Electrical Transformer which provides a low reluctance path to magnetic flux. Core keep all magnetic flux within it. And link maximum flux with coil.

A Transformer core made of thin soft iron sheets to provides a low reluctance path to the magnetic flux.

Why transformer core used ?

We know transformer work on basis of principle of Mutual induction.

According to this, the magnetic flux produced in one winding (primary winding) links to another winding (secondary winding).

And for this work we use core in transformer to provide low relcutance path to magnetic flux so that maximum magnetic flux link with other coil.

We know that opposition of magnetic flux is called magnetic reluctance. And it persists in the core either it is small or larger according to the material used in core.

If Magnetic flux produced by a primary winding is passing through air or any other nonferrous material used to link the magnetic flux to secondary winding. It will cause a low amount of magnetic flux due to high reluctance of Material.

So we need to provide a low reluctance path between the primary and secondary windings of the transformer, so that the loss in the magnetic flux can be minimized. For this purpose, we used a magnetic core usually made up of high-grade silicon steel, is used. This magnetic core reduces the magnetic losses and conveys a relatively higher amount of magnetic flux from primary winding to secondary winding. This practice increases the efficiency of the transformer.

Type of Core

The following two types of transformer core constructions are used

- Core type construction

- Shell type construction

Core type configurations are used for high voltage/high power needs. Although their power losses tend to be higher, the windings in core type are readily available and so maintenance is easier than in shell type transformers. Finally, because in core type transformers the windings are placed on separate legs, more copper is required in the manufacturing of core type transformers.

On the other hand, shell type cores are used for lower power applications. They have less energy losses, but maintenance is harder because the windings are harder to reach. The better energy containment is due to the windings being closer to each other and the magnetic flux having a closed path around the coils on which to travel. In contrast to the core type, shell type transformers allow for natural cooling. The mechanical strength of shell type transformers is also higher.

Losses in Transformer core

- Hysteresis losses

- Eddy current losses

Both type of losses depend upon magnetic properties of the materials used to construct the core of transformer and its design. So these losses in transformer are fixed and do not depend upon the load current. So core losses in transformer which is alternatively known as iron loss in transformer can be considered as constant for all range of load.

Hysteresis loss in transformer:

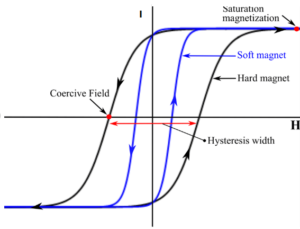

Hysteresis loss is due to reversal of magnetization in the transformer core. This loss depends upon the volume and grade of the iron, frequency of magnetic reversals and value of flux density. To Reduce the hystersis loss in transformer we used ferro-magnetic material as it can easily get magnetised and demagnetised. And we used the material in the core should be high permeability in nature. Because which material having high permeability it having low hysteresis loss. Permeability of a material may be understood from below diagram.

H is the Magnetic intensity, is the external factor which magtise the Material .

Or

Magnetic field intensity is generally the strength of the magnetic field induced around the magnet. The SI unit of magnetic field intensity is amperes per meter or Tesla. Magnetic field lines play a vital role in denoting the direction of the magnetic field.

And I is Magnetisation , means how a material get magentised by the Magnetic instensity.

or

Magnetisation is a vector quantity that measures the density of permanent or induced dipole moment in a given magnetic material.

Eddy current loss in transformer:

In transformer, AC current is supplied to the primary winding which sets up alternating magnetizing flux. When this flux links with secondary winding, it produces induced emf in it. But some part of this flux also gets linked with other conducting parts like steel core or iron body or the transformer, which will result in induced emf in those parts, causing small circulating current in them. This current is called as eddy current. Due to these eddy currents, some energy will be dissipated in the form of heat. To Reduce the eddy current we used stacking layers of thin lamination, rather than a core built from one solid piece, has the effect of reducing eddy currents and heating.

Why CRGO core is used in transformer ?

CRGO means CRGO(Cold rolled grain oriented) Silicon steeel core used in transformer. Why silicon steel used in CRGO core beacuse Silicon steels are ferritic alloys of iron and silicon that have magnetic properties. The silicon additions improve magnetic softness and increase the electrical resistivity. And by use of CRGO core Hysteresis losses can be reduced by using material that has less area of the hysteresis loop. Hence, silica steel or CRGO steel can be used for designing the core within a transformer because it has extremely less area of the hysteresis loop

We can say in the elctrical transformer core made of CRGO silicon steel as it is having high permeability and low losses as mentioned above.